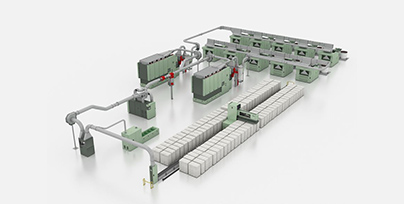

C.N.I.P provides best services for installation of old spinning machinery and restart the spinning machinery. we provide construction work, electrical work, Pipe line works, installation of moisture systems, storage rooms, maintenance room, installation of the machinery which provided by client, Our technical team visit the site and provide best site support to our clients.